Port Credit Marine Surveys & Yacht Delivery Society of Accredite Marine Surveyors  American Boat & Yacht Council  BoatUS®

|

STOOPID BOAT TRICKS BY BOAT BUILDERS I was once admonished by a prominent industry insider for having the temerity to oppose the opinion of a boat builder who had been building boats for thirty five years and knew what he was doing. That prompted this feature of "Stoopid Boat Tricks By Builders". Most new boats sport a sticker saying "NMMA Certified using ABYC® Standards". Note the significant semantic difference between " using ABYC® Standards " and " to ABYC® Standards ". Others have a label saying "Proud Member of ABYC®". Does this mean they build to the standards ? I am occasionally asked if its worthwhile to have a new boat surveyed. I usually advise against paying for a survey but suggest instead hiring me to spend a couple of hours going over the boat with you. I'd also suggest you think about a complete survey a couple of months before the warranty runs out. Take a look at the photos below and make your own decision. |

|

| Take a look around your boat, ever see one

of these labels ? They are extremely rare

on anything bigger than a runabout. Just like your car, every boat in Canada is supposed to have a label like this one where the builder states that the vessel was constructed in conformity with the legally required Transport Canada Small Vessel Construction Standards. Boats without this label should never have been allowed across the border and I have only ever seen one boat (excluding canoes etc.) that met all the legally required standards. Would you or our government accept this from GM or Mercedes ? Sure some of these non-conforming issues are small potatoes but some are significant safety issues. |

|

|

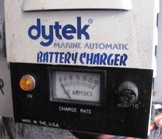

| Transport Canada TP1332E and ABYC "AC

& DC Electrical Systems" Standards

require that battery disconnect switches

be readily accessible. Transport Canada defines

readily accessible as "means capable

of being reached for inspection, maintenance

or usage under emergency conditions".

Do you think these switches under four heavy hatches are "readily accessible" ? If there is an electrical fire in the engine room (most common source of fire on boats) do you want to open those hatches to turn off the battery switch ? Mounting battery chargers over batteries is also prohibited due to the corrosive and explosive hydrogen gas produced while charging . Oh and by the way that battery charger is not ignition protected as required. The builder of this boat knew better. |

|

|

| My buddy Ted posed on this boat when it was

on the hard. Imagine this ............. You loose power in rough water at a harbour entrance. What are your chances of getting to the bow to get the anchor down before you are on the breakwall ? This dangerous design shows a complete disregard for the crew safety. Equally as bad are the express type cruisers with steeply angled, rounded cabin trunks and no side decks. Let's see you get over that windshield to get to the anchor in rough water, Hell, most can't do it in calm water to dock the boat ! |

|

|

| When we opened up the crack in the bottom

of this powerboat we found no glass

fibers,

Thats right they forgot to put in the

glass

that makes it "fiberglass ! A 2' X 3" area of the bottom had all the strength of a potato chip. |

|

|

| February 2007 - This brand new 2007 boat

in the showroom with an illegal fuel filter.

This filter does not have a heat shield and

is not fire rated as per Transport Canada,

United States Coast Guard, National Marine

Manufacturers Association or American Boat

& Yacht Council Standards but it does

appear to meet the builders standards ! This boat had neither the required fire port (alternate to fixed extinguisher in the engine compartment), carbon monoxide, smoke or propane fume detectors. Why does someone laying out 200 - 500k put up with this nonsense. but they built it that way ! |

|

|

| Gasoline engine compartment ventilation.

If nothing else.....get this one right, it

can kill you 2 ways. Your choice ........

Carbon Monoxide poisoning or an obituary

written from the Sunnybrook Burn Center. Click on the diagram

at right to link to a separate and

more detailed

article on this issue. The early symtoms

of CO poisoning are virtually identical

to

sea sickness so when you were feeling

nauseous

were you really poisoning yourself

? I'll never understand why more gasoline powered boats don't blow up ! Easily 80% of the gas powered boats I survey do not have proper ventilation of the engine compartment. This one deserves an article on its own so take a look at Gasoline Engine Compartment Ventilation. |

|

|

| This Regal 2665 at the Toronto Boat show

sported labels saying it complies with NMMA

standards which in turn claim to use ABYC

Standards for ventilation. ABYC Standards prohibit engine compartment ventilation on the stern due

to the high potential for CO poisoning. The same standard prohibits intake and output vents

from being within 18" of each other

but this boat had one intake duct and one

output duct connected to the same plenum

shared by the three round vents (near center).

The other two round vents share another plenum

and even if they were used would still be

adjacent to the output vents. Just below the transom door is another label warning of the dangers of CO ..... They should have called this one the ...... IRONIC 2665 |

|

|

| Below - The builder put those lovely curved engine compartment vents around the stylish stern where they should not have been in the first place | Then covered them up with some beautifully stiched canvas. I am convinced there were no fatalities only because the boat never left the dock. | |

|

|

|

| The builder of this sailboat thought it would be a good idea to vent the engine compartment directly into the cabin. Gas fumes & bilge stink let alone carbon monoxide poisoning. How come they never got sued ? |  |

|

| The powerboat (below left) required three passenger benches to be unfastened and four heavy deck hatches to be removed for engine access. The sailboat (lower right) has no place to put these very heavy steps once the engine is uncovered so you have climb over it to check the oil. Maybe the boat builders are right and no one ever checks anyway. | ||

|

|

|

| The outlet (below left) is on a brand new $1,000,000.00 motor yacht and the one on the right a new $600,000.00 trawler. Some builders still don't know there are standards. If an electrician installed outlets like this in your house he'd lose his license and you'd have a fit but it didn't seem to bother the purchasers of these boats. | ||

|

|

|

| Many boat builders put AC and DC systems on the same panel. In Canada this is illegal. | Heres why ! ..... think about it. I'm sure

. you'll get it before some builders. |

|

|

|

|

| Right up to the 80's and early 90's sailboat builders were putting solid core copper AC conductors in boats, just like the stuff in your home. They kept doing it long after the law required otherwise. The photo below left shows why it should not be on board. The photo below right shows it being used as a lightning bonding conductor on a 2008 high end sailboat. I could not photograph it but this solid copper lightning bonding conductor goes from the chainplate rod to the fuel tankl ! | ||

|

|

|

| Another lightning bonding conductor from

a French sailboat builder (at right) and

again completely non-kosher The issue with solid core copper is that it becomes brittle with vibration and breaks down. The braided conductor at right is supposed to be at least #4 AWG, tinned, stranded wire as lightning will vaporize the braided stuff. |

|

|

| Even today some builders are using aluminum for waste tanks (like the rotted tank below right with a galvanized steel elbow which ate through the tank. Everyone knows aluminum and urine don't get along well together and if you throw in another metal you also get galvanic corrosion. |  |

|

| What kind of moron installs tankage and then

builds the boat around them. Ever have

to

cut a tank into pieces to get it out

? Of course it wouldn't have leaked in the first place if it had been properly installed. |

||

|

|

|

| PROPANE - Another one that can kill

. Many European and Far East builders still

can't get this right but most of the

North

American builders are so shy of litigation

that they have smartened up. |

||

| Below - This 2008 Taiwan trawler like almost all trawlers with flying bridges has a propane tank under the bridge helm totally exposed to non-ignition protected wiring. If it leaks it will drain right down the steering/throttle/shift races to the cabin or even the engine compartment - BANG ! | Below - Transport Canada says any appliance must be installed in accordance with manufacturers ..instructions. Paloma says of their instant water heater "DO NOT INSTALL IN A BOAT". Ontario boat builders installed thousands of these units.. | |

|

|

|

| Below - Notice the CE Approved label on the steering pedestal of this French sailboat then the factory propane installation under the seat and open to the cockpit. Did you know that CE boats are self approved by the manufacturer ? | Below - See the side loading propane locker above the engine compartment, over three AC breakers and the battery box on this Jeanneau powerboat at the 2012 Toronto boat show | |

|

|

|

| Below - How long until that razor sharp fiberglass edge cuts through the propane line on this gimballed stove ? | Below - How long before this badly bent hose develops a leak at the swaged joint ? | |

|

|

|

| Below - Typical Niagara / Nonsuch junction inside the boat and held together with gear clamps. What the hell was he thinking ? | Below - No, no, no .... Another late model French boat with multiple junctions and valves inside the vessel. Other than appliance connections ALL joints must be within the propane locker ! | |

|

|

|

| At right - The solenoid shut-off switch,

propane fume detector control and fire extinguisher

are behind the burners. Do you want to reach through flames to shut off the propane and put out a fire. It doesn't get much stooopider than this. To see how a safe propane system should be installed take a look at Safe Propane Installations on Boats. |

|

|

| More quality control - This cheap plastic throughull is 1" above the water line and seriously UV degraded. It could be picked apart by my fingernail. The caulking shows that an attempt had been made to stop it leaking. Should this be impacted by floating debris, the bilge pump will not be able to keep up with the incoming water. Cheap plastic throughulls near the the waterline are more prevalent on powerboats for some reason. |  |

|

| Many builders are now using these cuff fittings, I don't get it ! only the friction of the ribbing on the hose is holding it in place as the clamps are on the cuff and not the hose and you can see the leak. |  |

|

| What you see at right is becoming a rare commodity ... a properly installed bronze seacock with integral flange bolted to an epoxy coated backing plate. |  |

|

| SEACOCKS - Serious corrosion can occur through

bad electrical installations, poor choice

of materials or over the last few years very

questionable alloys from China like the now

famous Groco seacock recall . The stainless steel in these seacocks .....

wasn't. The broken propeller shaft

(below

left) is also a questionable alloy.

|

||

| The photo at right shows a typical (very)

European installation. Lets count the things

that are wrong. 1. There is no base flange for support. this is not a "seacock" but a ball valve on a throughull fitting. 2. Backing plate ? of course not. 3. The clamps are made of two different metals providing a source of galvanic corrosion when they are wet, these clamps will rust. 4. The ball valve is made of nickel plated brass, not a huge problem in fresh water but can disintegrate rapidly in salt water. read up on "dezincification". 5. Bronze throghull with a chromed nut (?) metal not determined. More breeding ground for galvanic corrosion. 6. NPS elbow threaded to NPT ball valve. See the next photo for an explanation of this shockingly common feature of European boats. |

|

|

| This photo show a tapered thread (NPT) coupler

with a straight thread (NPS) thoughull and

an NPT pipe. You can see that the connection at right is fully engaged but the connection at left is secured with only a few threads. So imagine ... mix and match thread types, mix and match metals and off you go cruising south in salt water. These issues are shockingly common on European boats. |

|

|

| This is what happens to brass throughulls

when connected to other metals and

then put

in contact with salt water. I strongly recommend you read Paul Stevens article #1 Paul Stevens article #2 on this issue, they are truly eye opening. |

|

|

|

If you found this interesting, check out

...... Stoopid Tricks By Boat Owners and Stoopid Tricks By Surveyors Unlike the automotive and RV industry there are no government agencies hanging over the boat builders shoulders and the only consumer protection agency looking out for us is BoatUS® whom I strongly recommend you support (even in Canada). Keep up to date with my Marine Surveyor's NEWSLETTER. |

|