Port Credit Marine Surveys & Yacht Delivery  Your delivery crew Society of Accredited Marine Surveyors  American Boat & Yacht Council

|

Oil Analysis as a part of your marine survey

Is it worth the money ? Absolutely Yes ! ........... maybe not ! |

|

| Oil analysis is a testing program used to monitor lubricating oils in order

to determine wear of metal components.

This

is not limited to engines but can also

highlight

potential problems with gear reduction

units,

hydraulic systems and fuel. Like so much else in boating this ain't rocket science. Go to your local auto parts store, UAP/NAPA, Cawthra Automotive etc. and ask for an oil analysis kit. They will charge you 30-40 bucks and it will come with all instructions and a pre-paid envelope to mail your sample to the lab but read the rest of this before you run out the door. Once you receive the report you may want to buy your favourite mechanic a beer while he translates it for you. Look at it this way, you can afford the beer 'cause you didn't have to pay him $100.00 to pick up the kit from the autoparts store and draw the sample. The kit will provide you with instructions, a container for the oil and a questionaire that will ask the brand, weight, hours on oil, make and model of engine, engine hours and a few other basic questions. some kits even supply a tube and plastic bellows type pump to draw the oil through the dipstick tube. Take a look at this article on Nine Reasons Why Oil Analysis Programs Fail. |

Its not pertinent but I like to have photos of boats in my articles so here is a shot of the Nordica 20 sailboat my mechanic buddy Robert Wainwright is turning in to a mini-tug |

|

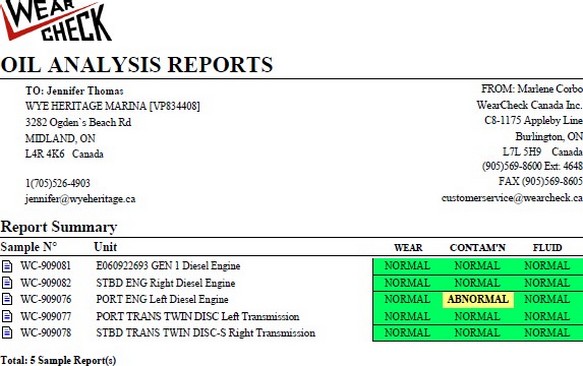

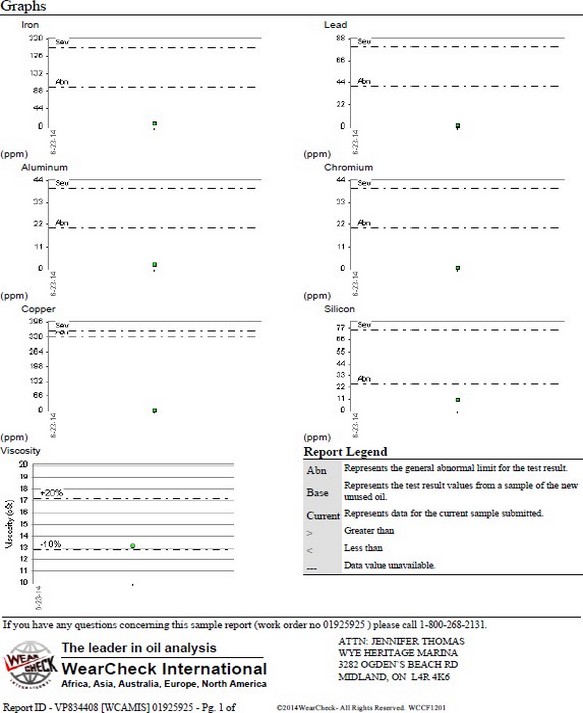

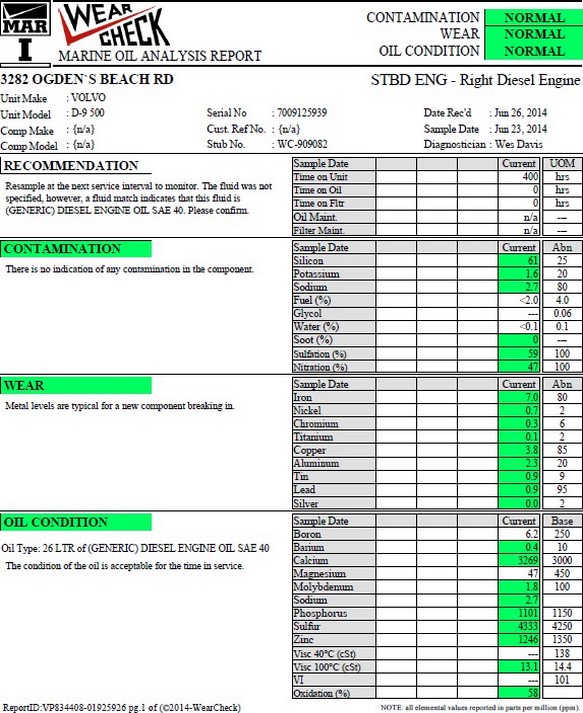

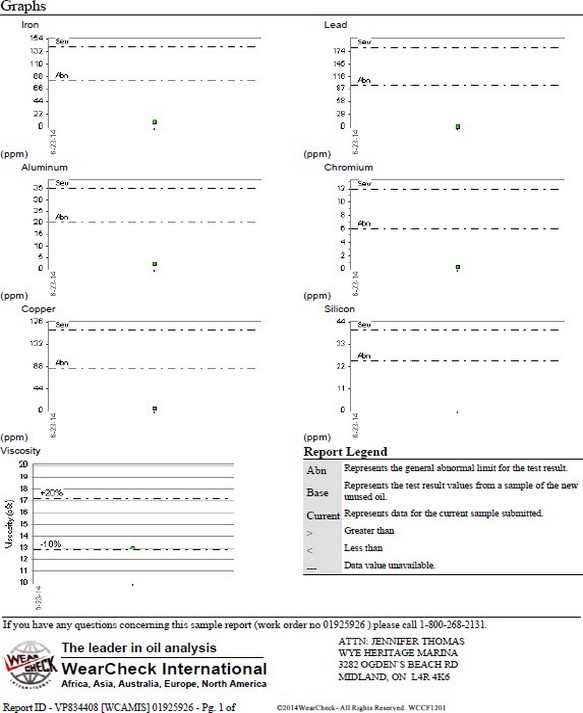

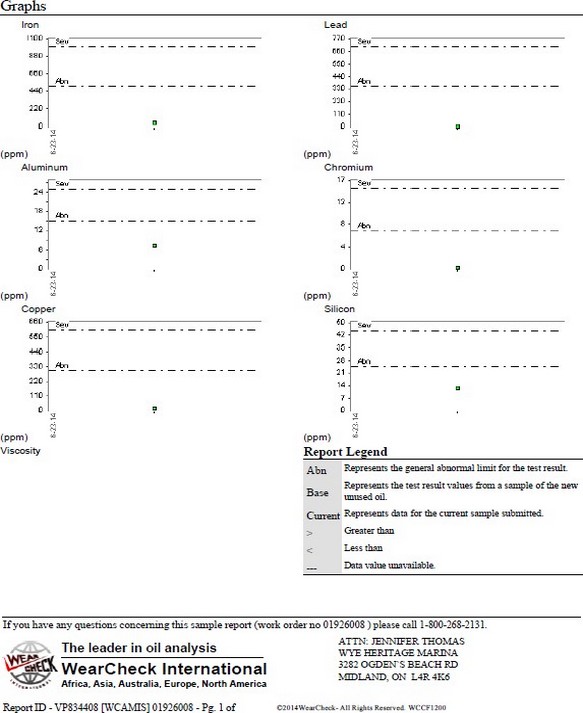

| Once supplied with the sample most labs will

send you a report within the week. For the analysis to be of value you must

answer all the questions on the questionaire.

The lab must know what oil is in the engine

as all have proprietary additives that affect

the chemical analysis, so the lab must have

some baseline information to begin with.

How long has the oil been in the engine and

how many hours are on it ? Every report will

show some contamination but unless you know

how much abuse the oil has taken, how can

you know if the contamination is normal or

excessive ? It's also important to run the

engine up to temperature before drawing the

samples as this ensures any contaminants

will be in suspension and give much more

accurate reading. If you are purchasing a boat that has not been used this year or since its last oil change, an analysis will tell you absolutely nothing as the oil has not had a chance to accumulate contaminants. If you draw your sample from the bottom of the oil pan on a boat that has not been used in some time the results may be unfairly pessimistic as the contaminants will have settled to the bottom. If you draw the sample from near the top of the oil pan an overly positive report may result. Even a highly qualified mechanic may not be able to tell you much from a one-off test except for catastrophic conditions which would likely be noticed under normal sea trial conditions anyway. A proper diesel engine survey including injector inspection and compression tests cost much more than a gasoline engine. A good diesel mechanic can tell a lot about a diesel engine just by looking at it and running it under load. It's up to you ..... you pays your money and takes your chances. The perfect analysis ..... Use the same brand and weight of oil .... always. Try to stick with the same source for your testing because report style and content can vary. Take the sample at the same time of year every year and try to take the samples with the same number of running hours on the engine every year. You may have noticed that I underlined the word program. I did this to emphasize that oil analysis should be a routine part of your maintenance program and not just a one-off when you are buying a used boat. If you do an annual oil analysis with a proper log of oil type and usage you would have a very accurate picture of the condition of your engine within a few test cycles. For most pleasure craft this would mean an annual test at end of season before the oil is changed. It would be pointless to send fresh oil or oil with only a few hours on it to the lab. Building a history of oil contaminants and the hours it takes them to accumulate to a given level can provide warranty protection on a new boat and a useful early warning system of potential problems from valves, rings, pistons, cylinders, bushings, rods, camshafts etc. As all of these components are made up of various alloys it can be quite easy to identify a specific part that is degrading faster than we'd like. Among the contaminants accounted for in the analysis are water, glycol, sulfur, soot and a number of metals such as those listed below. |

||

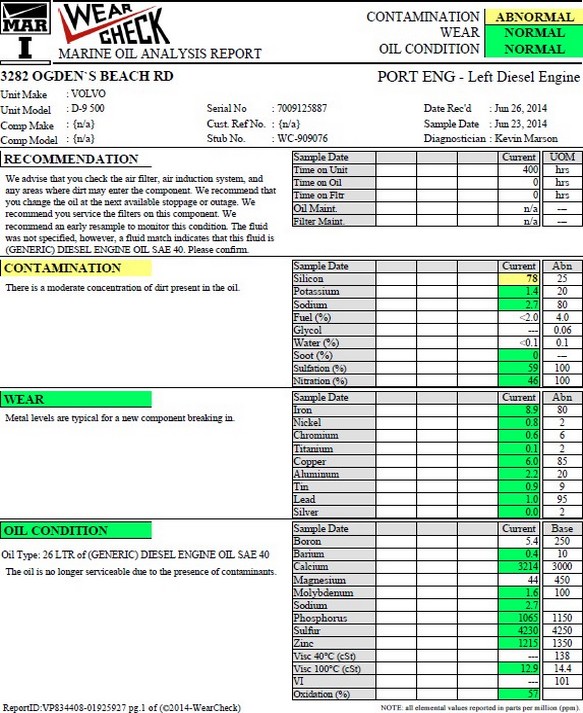

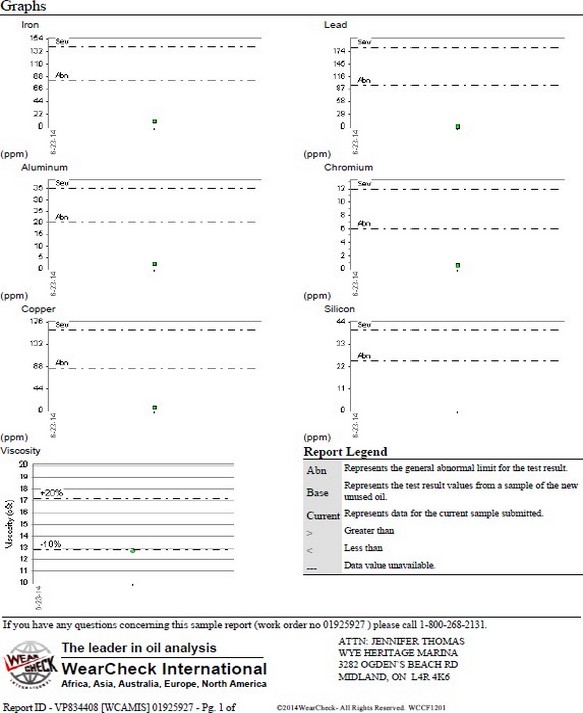

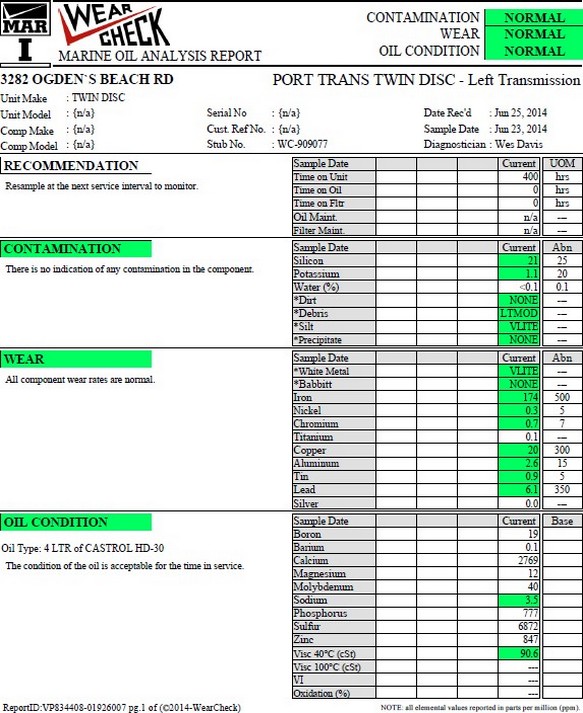

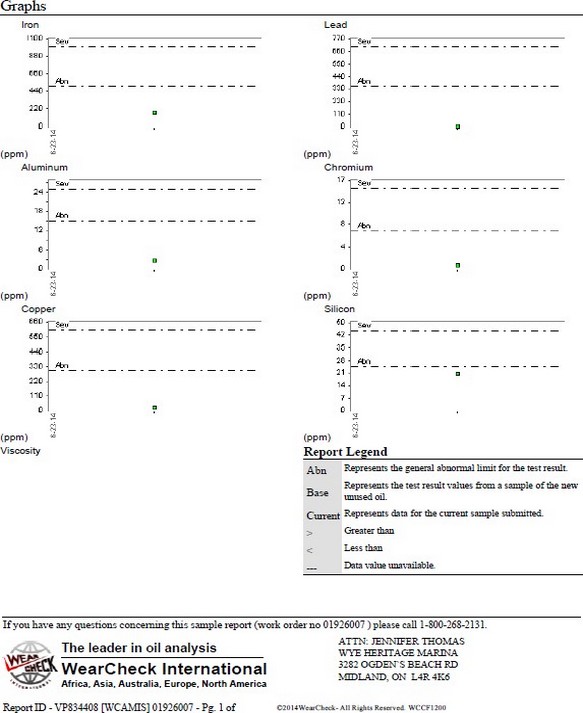

| Iron (Fe) | Indicates wear originating from rings, shafts, gears, valve train, cylinder walls, and pistons in some engines. |

| Nickel (Ni) | Secondary indicator of wear from certain types of bearings, shafts, valves and valve guides. |

| Molybdenum (Mo) | Indicates ring wear. Used as an additive in some oils. |

| Chromium (Cu) | Primary sources are chromed parts such as rings, liners, etc., and some coolant additives. |

| Aluminum (Al) | Indicates wear of pistons, rod bearings and certain types of bushings. |

| Tin (Sn) | Indicates wear from bearings when babbitt overlays are used. Also and indicator of piston wear in some engines. |

| Silver (Ag) | Wear of bearings which contain silver. In some instances, a secondary indicator of oil cooler problems, especially when coolant in sample is detected. |

| Copper (Cu) | Wear from bearings, rocker arm bushings, wrist pin bushings, thrust washers, other bronze and brass parts. In some transmissions, wear from discs and clutch plates. Oil additive or anti-seize compound. |

| Sodium (Na) | Coolant additive; used as an additive in some oils. |

| Silicon (Si) | A measure of airborne dust and dirt contamination, usually indicating improper air cleaner service. Excessive dirt and abrasives can greatly accelerate component wear. |

| Boron (B) | Coolant additive; used as an additive in some oils. |

| Phosphorous (P) | Antitrust agents, spark-plug and combustion chamber deposit reducers. |

| Zinc (Zn) | Antioxidants, corrosion inhibitors, anti-wear additives, detergents, extreme pressure additives. |

| Calcium (Ca) | Detergents, dispersants, acid neutralizers. |

| Barbium (BA) | Corrosion inhibitors, detergents, rust inhibitors. |

| Magnesium (Mg) | Dispersant - detergent additive, alloying metal. |