As purchased - September 2014 |

- -

June 2016 9' shorter mast with hammock :) |

COCKPIT

The cockpit did not drain, there were two

small, inadequate scuppers and there was

no arch in the deck to direct water to the

scuppers. There was a 1/4" high sill

around the hatch which was 3/4" higher

than the deck and a trip hazard so that water

backed up on the deck and flooded the engine

compartment/steering gear compartment.. We

had to build a new deck over the old to have

room to fit gutters around the hatch. There

was no propane locker so we had to build

one of those too, into the aft end of the

cockpit. Neither were there gutters around

the side locker hatches so those filled with

water when it rained.

We started with a new bimini / stern rail

and progressed through re-sking the deck

with an arch to improve drainage, the addition

of a proper propane locker, new hatches with

drain gutters. ( Can you imagine a huge engine

hatch with no gutters ? ) and Sharons impeccable

new non-skid.

|

.JPG) |

No propane locker, raised deck hatch without

gutters routinely flooded engine compartment.

|

Building new propane locker

|

Sharon fillets the new deck before glassing

over |

New gutters drain to scuppers, and

finished

propane locker

|

|

|

Enlarging the inadequate scuppers |

A little paint and new scuppers with be finished

|

New propane locker, new arched deck with

flush engine hatch with gutters,new stern

rails & propane locker |

Cockpit .... finito !

Finito ! |

RUDDER mod & bottom job

The odd shape of the rudder and lack of balance

(contrary to Benford's original design) meant

that a lot of the prop wash did not move

over the largest part, this made turning

at low speeds quite difficult without using

the bow thruster.

While hauled for fresh bottom paint we added

two 20" X 7" stainless steel "fish

tails". The greater surface area within

the prop wash and the 15° angle on the

tails has made a dramatic difference to turning

ability in close quarter manouvering.

Re-painted the bottom. How many wives would

get under the plastic with a sander, my wife

is awesome !

My photo is the aftermath of sanding with

goggles and a mask. That crap gets under

everything but Sharon looked as cute as a

button in her painting outfit.

PS. I'm too old for this stuff. I will never

do another bottom job ! |

|

|

|

My wife is so damned cute !

|

I didn't fare so well even with goggles,

suit and mask. What a crappy job |

WINDOWS -

Between September 2014 and June 2015 we installed

17 custom Bomon windows and one brass

port

hole. I've installed Bomon windows

on my

two previous boats so obviously I am

quite

pleased with them. The windows were

by far

the biggest job we will undertake on

Dirt Free as the old windows were simple wooden frames

over glass rabbeted into the structure.

The

damage done in getting these rotten

wood

frames off was substantial. We also

repainted

the entire superstructure and Sharon

did

all the non-skid after re-glassing

much of

it.

|

Days and days and days of sanding |

Sharon doing the new non-skid |

.JPG)

Caulking will NEVER seal plywood ! the screw

driver slides in like in butter |

.JPG)

First of 17 new windows going in |

|

|

|

|

|

New hatch and new structure glassed in place

ready to be trimmed out for the new

windows.

I had planned an entire morning to remove

the badly leaking butterfly hatch that

you

see in the "before" photo

at left

below ... it was completely rotten

and took

all of 30 seconds. The butterfly hatch

was

replaced with a heavy duty aluminum

frame

unit. |

|

|

New Bow rail, $50.00, Stachions and life lines free from

a boat being scrapped, 55lb. Rocna

$300.00.

All in Canadian dollarettes so actully

close

to free :) |

|

PILOT HOUSE -

DOORS - The pilot house doors are securely mounted

on sail tracks at the top, there was

no track

or method of securing them along the

bottom

so they banged constantly in choppy

weather

and opened whenever they felt like

it. The

plan is to rebuild them and fit them

with

matching Bomon windows then devise

a securing

and locking method along with a lower

track

then replace the forward wooden (rotten)

track with aluminum. We'll be doing

this

job over the winter under shrink wrap

|

|

|

|

|

.JPG) |

|

|

|

|

BOW THRUSTER -

Hull shape, smallish propleller, smallish

rudder with flow directed low all add

up

to the fact that Dirt Free does not like to turn at low speed so the

old single crew trick of hammering

the throttle

with the rudder hard over and then

going

to reverse does not work as well as

it did

on my other single screw boats so a

thruster

is the immediate fix. Later on I will

make

some rudder modifications and see if

that

helps.

Note the illegal below the sheerline

placement

of the stern light. She also came with

no

forward running light or anchor light

and

had been cruised in that condition. |

.JPG)

First ..... cut a really big hole ! |

.JPG)

Slide tube into place |

.JPG)

Trim tube for flared fairing |

.JPG)

Add lots of filler then sand, sand, sand

and sand some more. |

.JPG) |

|

| INTERIOR |

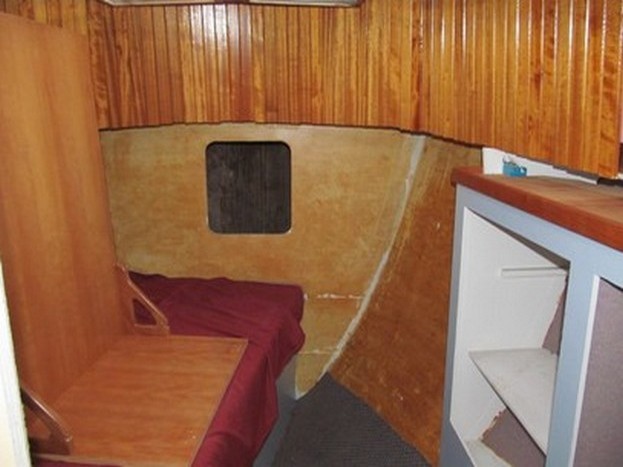

Typical "before" joinerwork |

SALOON

The entire saloon was panelled with yellow

painted plywood with the most amateur

joiner

work imaginable. There were so many

things

wrong that it's difficult to list them,

no

access to the bilges, leaking windows

, atrocious

joinerwork, an aluminum (dumb, dumb,

dumb)

waste tank that was inaccessible, a

head

compartment without a shower or any

means

of draining one, no refrigeration and

the

list goes on ..... |

Yellow painted plywood panelling, Hard

wood

floors glued to deck with no bilge

access |

Much more comfortable. Yes, that's a fireplace

|

More yellow painted plywood |

Love that fireplace |

.JPG)

Cut through floor to make bilge access |

XAwaiting photo |

.JPG)

Hardwood sole chiseled out a plank at a time.

Hinged bilge hatches being fitted |

New cork sole and hatches where none existed

before

|

.JPG)

Hinged engine compartment hatch integral

to settee fitted and functional

|

Hard to believe it was built with no bilge

access ! Table now retracts. |

Tore the wall out behind the forward dinette

bench ... also torn out |

|

Fixed table and two dinette benches |

Retractable table and one less dinette

bench |

|

Teak Teak frame cupboard doors with laminated

glaas panes |

Got rid of this wall with sliding privacy

pabel and settee The ceiling, the only thing worth keeping. |

Now we have much more room and much more

storage space |

GALLEY -

Consisted of a stove, sink and delaminating

formica countertop |

First - install a refrigerator |

X X |

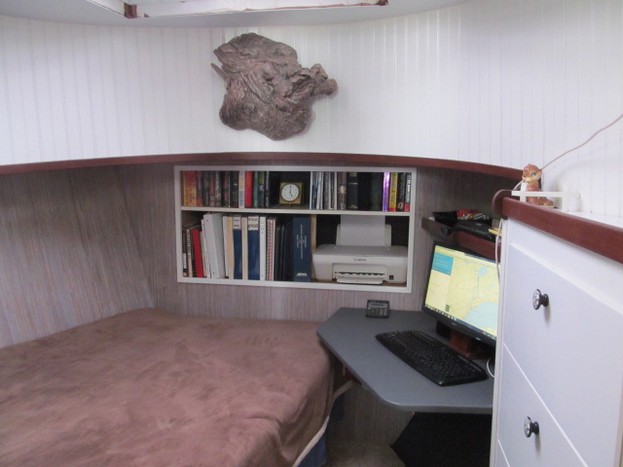

| V-BERTH |

Carpet removed from walls |

Nice piece of drift wood huh ? |

Horrible carpeted walls |

Beaded board walls and custom headboard by

Sharon |

Before |

Sharon has always wantee crown molding. Who

am I to deny her !

|

Mid- way |

Then she asked for hidden lighting behind

the molding..... I can deny this woman

nothing

|

HEAD / SHOWER

The head compartment had hardwood floors

which we ripped out. We then built

a drain

pan so we could install a shower and

covered

all surfaces with the same FRP panels

we

used in the saloon and elswhere. |

.JPG) |

Awaiting photoX |

PILOT HOUSE

The ubiquitous yellow painted plywood,

a

wheel that will impale you in rough

seas. |

X |

XAwaiting photo |

|

Awaiting photoX |

.JPG) |

XAwaiting photo |

| ENGINE |

|

Awaiting photoX |

|

XAwaiting photo |

|

Awaiting photoX |

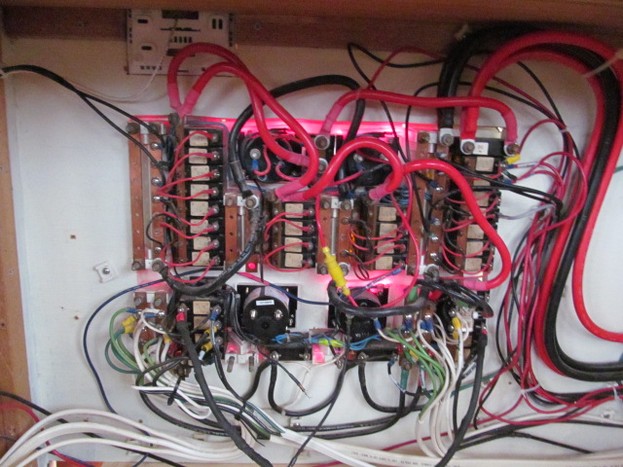

| ELECTRICAL |

|

xAwaiting photo |

.JPG) |

Awaiting photox |

|

Awaiting photoX |

|

Awaiting photoX |

|

Awaiting photox |

MAST AND DINGHY (and hammock)

We Cut 9' off the mast so we could do the

New York State Canal System then rigged

a

hammock to the boom. At some point

this summer

the boom will be rigged to lift our

new dinghy

on to the cabin trunk If all goes well

we

will also rig the mast with a steadying

sail.

I don't really think it will accomplish

much

but it will look kinda neat especially

if

we can get a tanbark square top.

|

-

-