Port Credit Marine Surveys & Yacht Delivery  |

Gasoline engine compartment ventilation safety

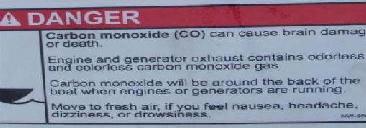

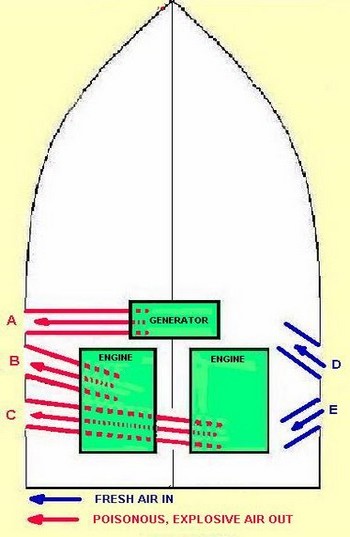

! The majority of twin engine gasoline powered boats and a very high percentage of single engine boats (sailboats included) I survey have improperly and unsafely ventilated gasoline engine compartments. Aside from the obvious explosion potential of gasoline vapour laden air is the insidious potential for CO poisoning which closely mimics the symptoms of seasickness. Why you should be concerned ….. Two reasons ….. 1.) Carbon monoxide is poison. 2.) Gasoline fumes can explode. There is no bigger safety leap you can make that is so easy and so cheap to do right. This is so simple and so inexpensive to do right that I find it hard to believe so many boat builders still get it wrong. I am not talking about older boats here. Check out the new models in the showroom and you'll be hard pressed to find one done right. Is your family worth $20.00 worth of flexible duct work from your local hardware store ? While this issue is critical on gasoline fueled boats, CO from diesel can also be an issue. Diesel does produce much less CO than gasoline but you must remember that CO poisoning is cumulative and will build up over hours or days and may take up to two weeks to leave your bloodstream. CO from a diesel is unlikely to kill you but the cumulative effect on a long trip can make you ill. For more on CO take a look at Carbon Monoxide Poisoning. Note : Gasoline fumes are heavier than air and will collect in the bilge. CO is near buoyancy neutral and will drift with the air. The following recommendations are based on ABYC® " Ventilation of Boats Using Gasoline" Standard H-2, with a little common sense thrown in. The diagram at below right shows a properly ventilated engine / fuel compartment. |

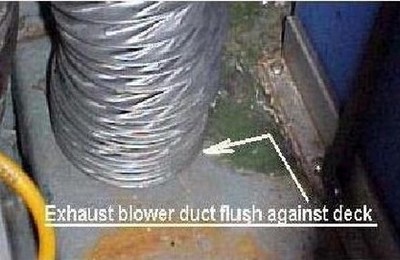

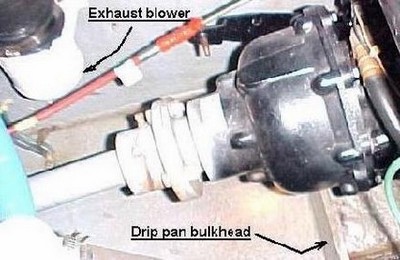

1. All three powered exhaust ducts draw air from under their respective engines. Gasoline vapours are heavier than air and will seek the lowest level. The space directly below the engines may not be the very lowest level but are generally bordered by tall stringers which contain the fumes to these areas. The whole exercise here is aimed at drawing gasoline or CO fume laden air from these areas and directing it overboard. 2. ABYC® requires one blower for "each gasoline engine used for propulsion". I think they screwed up here and forgot about the generator. Did they think generators couldn't leak gas ? I always include genny blowers in my recommendations. Once again, stringers or other structural frame members can trap heavier than air vapours so it's essential that each area have its own blower. 3. All powered exhaust ducts should exit on the same side of the boat with fresh air intakes on the opposite side. Neither intakes nor outputs should be on the stern of boats with accomodation spaces. If intakes and outputs are on the same side you may end up re-circulating the same gasoline vapours. Many boats are produced with plenums/louvers on each side then intake and outputs connected to the same plenum on one side ... sheer laziness on the production floor. More often than not I see intakes and output connected to the same plenum which is a surefire way of re-circulating vapours rather than ventilating your engine compartment. ABYC® standards also dictate that intake/outputs shall not be on stern. With intakes and outputs at the stern, The "station wagon effect" may push fumes back in through the intakes or directly into the cockpit.. |

|

| Some believe that it is not necessary to

run the blowers at cruising speed and

turn

them off as soon as they are under

way. I

prefer to see blowers run whenever

the engines

or generator are running but they most

definitely

should be run when the vessel is moving

at

slow speeds and at anchor if the generator

is running. A few other ABYC® requirements…. Exhaust ducts must terminate in the lower 1/3 of the bilge but above the normal accumulation of bilge water. Exhaust duct ends must be no closer than 24" to intake openings. Air intakes and exhaust outlets shall be no closer than 15" from gasoline fill and tank vent fittings. Ventilation outlets must remain outside of weather enclosures. You will get better cross ventilation if the intake ducts are high in the engine compartment. All duct ends must be secured. ABYC and NMMA also prohibit ventilation intakes or outputs at the stern (on boats with accomodation spaces) due to the "station wagon effect" and the fact that people tend to hang around the swim platform with the generator running. Of course none of this makes any difference if you don't use your blowers. Canadian law requires that blowers be run for a minimum of 4 minutes before starting your engines. Keep an eye out this season and watch most people flick the blower switch and immediately fire up their engines. The insurance investigation takes place shortly thereafter. |